3043D

Compact Tractor

3-series-compact-tractors

- Standard 4wd for Maximum Traction

- Heavy duty drive train with a gear drive transmission 8F/8R

- On-board diagnostics including Service Advisor

Apply For FinancingBuy OnlineMaintenance Plans

Pricing excludes attachments

View Product Brochure

10 Year Warranty Details

60 Day Promise

Features

Reliable gear-driven transmission provides optimum tractor performance

The 3D Tractors are available with a gear drive transmission with eight speeds in both forward and reverse directions. It includes a drivetrain built with heavy-duty components like those used in some John Deere utility tractors. These components ensure a rugged and durable machine.

- The spiral bevel gear of the 3D machine is larger in diameter than comparable tractors.

Column-mounted forward and reverse lever for increased efficiency and comfort when changing directions.

Fender-mounted gear shift lever for more comfortable shifting

Safety features of the 3D Series Tractors include:

The tractor will only start with the forward/reverse, range, and gear shift levers in neutral.

The engine will shut off if the operator leaves the seat unless the forward/reverse, range, and gear shift levers are in neutral.

The engine will shut off if the operator leaves the seat and the power take-off (PTO) is engaged.

Ergonomic and optimized shift levers

Forward/reverse lever

Forward/reverse lever

Range lever

Range lever

Operator station

Operator station

Key John Deere advantage - A column-mounted forward/reverse lever is a more ergonomic alternative to the floor-mounted design of the competition. Having controls at the operator’s fingertips allows for an effortless change in directions at any time.

Gear shift lever

Gear shift lever

The 3D is much easier and more comfortable to operate when shifting between gears. The fender-mounted gear shift lever provides the ideal location and placement for the operator’s arm.

Clean and simple operator station is comfortable and convenient

Clean and simple operator's station

Clean and simple operator's station

An uncluttered design gives operators of all sizes plenty of room to be comfortable. Color-coded controls are located on either side of the operator.

- Contoured, comfortable seat enhances operator comfort.

- Seat position adjusts fore and aft

- Seat flips forward for protection from the elements

- Flat operator platform provides for easy entry to/exit from the tractor.

- Folding Roll-Gard™ rollover protective structure (ROPS) and retractable seat belt increase operator safety.

Operator presence system:

- If the operator leaves the seat when the forward/reverse and range lever are in gear, the engine shuts down.

- If the operator leaves the seat when the power take-off (PTO) is engaged, the engine shuts down.

Left-side step

Left-side step for easy entry/exit

Left-side step for easy entry/exit

- The left-side step allows for easy access on and off the tractor.

- Foot platform has a non-skid surface for sure footing.

Seat

Seat

Seat

The thick, soft padding on this seat provides a smooth and comfortable ride.

- Seat flips forward for protection from the elements.

- Adjustable using the fore and aft lever located under the seat, the seat slides on ramped rails to provide comfortable access to all controls.

Instrumentation

Instrument panel

Instrument panel

Easy-to-read instrument panel includes the following:

- Tachometer

- Low oil pressure indicator light

- Battery discharge indicator light

- PTO engagement indicator light

- Signal/hazard lamp indicator lights

- Multifunction liquid crystal display (LCD) display (hours, filter cleaning information, PTO speed, etc.)

- Filter cleaning status indicator light

Fuel tank and gauge

Rear-mounted fuel tank and gauge

Rear-mounted fuel tank and gauge

All 3D Series Tractors come standard with a fuel gauge that is easy to read from the operator's station to ensure operators do not run out of fuel. The fuel tank is also located on the rear of the tractor to allow for easy refill.

Safety

Operator presence switch (OPS) in seat:

- OPS requires the operator to be in the seat to operate the transmission or PTO.

- ROPS is designed to meet or exceed American Society of Agricultural and Biological Engineers (ASABE) safety standards.

- Reflective ROPS strips for better tractor visibility.

- Seat belts are in base equipment on all John Deere compact utility tractors.

- Key switch interlock prevents bypass starting.

- Visual PTO warning light on the instrument panel alerts the operator when the PTO is running.

- Turn signal and flashing warning lights operate according to ASABE standards.

- Slow-moving vehicle (SMV) sign is provided for road transport.

Park brake

Park brake

Park brake

Instrument panel has an indicator light for the park brake.

Two-post Roll-Gard ROPS

Roll-Gard ROPS

Roll-Gard ROPS

3D Series Tractors are equipped with Roll-Gard ROPS. These folding ROPS meet the ASABE standards for compact utility tractors.

NOTE: The use of seat belts is recommended at all times when operating the 3D Series Tractor with the folding ROPS upright.

An optional canopy is available to help protect the operator from the elements.

Optional two-spool rear selective control valve (SCV) for superior implement performance

Optional rear SCVs

Optional rear SCVs

3D Series Tractors can be equipped with a field-installed rear hydraulic remote kit, providing two additional hydraulic spools on the back of the tractor. This kit can be field installed on a tractor with a loader or without a loader.

The functions are completely separate from the loader. These rear remotes can be hooked up to a wide variety of implements and attachments such as follows:

- Hydraulically angled blade

- Hydraulically controlled chute/spout on a 3-point hitch-mounted snow blower

- Hydraulic scarifiers on a box blade

- Many other hydraulic rear attachments

This versatile kit gives 3D Series Tractor operators the options they desire for putting their tractors into a wide range of tasks.

The first spool is equipped with a float position, giving the operator the ability to contour the landscape and improve the final grade with certain implements.

NOTE: Neither of the spools in this kit are equipped with a detent position; therefore, they should not be hooked up to anything with a motor, as the valve was not designed to be run open. The kit is designed for momentary, on-demand hydraulic flow such as moving a cylinder.

The approximate installation time is 1 hour to 1.5 hours.

Optional iMatch™ Quick-Hitch feature allows for easy implement hookup

iMatch Quick-Hitch (LVB25976)

iMatch Quick-Hitch (LVB25976)

One of the greatest operator concerns involves difficulty in attaching tractor implements. John Deere has addressed this issue with the iMatch Quick-Hitch.

The iMatch Quick-Hitch provides easy hookup and a guaranteed fit for all Category 1 implements that are designed to meet the American Society of Agricultural and Biological Engineers (ASABE) Category 1 Standard S278.6 for quick-attach hitches.

- All implements require a set of bushings for the attachment to fit and work properly with the iMatch Quick-Hitch. One set of bushings comes with the iMatch Quick-Hitch.

NOTE: The bushing set can be seen in the picture above. These bushings allow the hooks on the iMatch and the pins on the implement to fit together properly. All other implements (box blades, tillers, rear blades, etc.) will require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier (see dimensions below).

- Upper bushing

- Inside diameter: 1.93-1.95 cm (0.76-0.77 in.)

- Outside diameter: 3.15-3.18 cm (1.24-1.25 in.)

- Lower bushing

- Inside diameter: 2.24-2.26 cm (0.88 to 0.89 in.)

- Outside diameter: 3.63-3.66 cm (1.43 to 1.44 in.)

Excellent serviceability reduces operational costs and improves productivity

Regular service and maintenance are essential to the performance, productivity, and longevity of the tractor.

Easy access to most regular service points minimizes service time.

Tractors are equipped with extensive onboard self-diagnostic capabilities and are fully compatible with the John Deere-exclusive Service ADVISOR™ system.

Hydraulic oil service interval increased to 1200 hours when using Hy-Gard™ products. Hydraulic oil filter will need to be changed every 400 hours.

Fuel tank is located on the rear of the tractor to allow for easy access when fueling.

Fuel tank on rear of the tractor

Fuel tank on rear of the tractor

- Four quarter turn fasteners allow operators to easily remove the engine side panels to access the engine compartment

Easy access to engine compartment

Easy access to engine compartment

- Daily service requirements are minimal and simple to accomplish. Most service interval requirements can be performed with a basic understanding of procedures and common tools.

Daily service is quick and easy

Daily service is quick and easy

All items in the daily service schedule can be performed without the use of tools:

Engine oil, hydraulic oil, coolant level, and the water separator can be conveniently accessed.

The engine can be easily accessed by simply raising the hood for more periodic maintenance checks.

NOTE: Always refer to the operator’s manual for complete maintenance and service recommendations.

Specifications

Compare the specifications of up to 4 models

| Key Specs | 3043d Current Model |

|---|---|

| Engine power (gross) | SAE J1995 rated power: 31 kW 41.6 hp 42.2 PS at 2800 rpm |

| Power take-off (PTO) power | 27.1 kW 36.3 hp |

| Steering hydraulics | 16.8 L/min 4.4 gpm |

| Implement hydraulics | 22.4 L/min 5.9 gpm |

| Hitch type | Category 1 |

| Lift capacity, 24-in. behind link arms | 944 kg 2081.2 lb |

| Standard transmission; forward/reverse | 8F/8R synchromesh shuttle shift gear transmission |

| Cruise control | No |

| Approximate shipping weight (open-station; cab) | Open operator station (OOS): 1288 kg 2840 lb Cab: Not applicable |

| Wheelbase | 1574 mm 62 in. |

| Engine | |

| Family | |

| Manufacturer | Yanmar® |

| Engine model | 3TNV86CT-KJPT |

| Engine power (gross) | SAE J1995 rated power: 31 kW 41.6 hp 42.2 PS at 2800 rpm |

| Power take-off (PTO) power | 27.1 kW 36.3 hp |

| Rated engine speed | 2800 rpm |

| Type | |

| Injection pump type | High pressure common rail direct injection |

| Aspiration | Turbocharged |

| Emissions compliance | Final Tier 4 |

| Cylinders/displacement | 3 / 1.57 L 3 / 95.8 cu in. |

| Number of cylinders | Three |

| Cylinder liners | Cast-in-block |

| Bore and stroke | 86 x 90 mm 3.39 x 3.54 in. |

| Compression ratio | 19.1:1 |

| Lubrication | Pressurized |

| Cooling system | Liquid |

| Air cleaner | Dual element |

| Engine torque at rated speed | 105.7 Nm 78 lb-ft |

| Fuel tank capacity | 36.7 L 9.7 U.S. gal. |

| Electrical | |

| Battery size | 600 CCA |

| Alternator (12-V) | 55 amp |

| Starter size | 1.4 kW 1.9 hp |

| Fuel system | |

| Type | High pressure common rail direct injection |

| Fuel consumption | |

| Transmission | |

| Standard transmission; forward/reverse | 8F/8R synchromesh shuttle shift gear transmission |

| Optional transmission; forward/reverse | |

| Left-hand reverser | Yes |

| Transmission gear ranges | Four gears and two ranges |

| Final drive | Spur gear |

| Brakes | Wet disk |

| Steering | Power steering |

| Clutch, wet/dry | |

| Clutch disk diameter wet clutch | |

| Axle capacity | Front 880 kg 1940 lb Rear 1600 kg 3527 lb |

| Creeper | No |

| Cruise control | No |

| Differential lock | Yes |

| Drawbar maximum vertical load | |

| Hydraulics | |

| Type | Open center |

| Pump rated output | Steering 16.8 L/min 4.4 gpm Implement 22.4 L/min 5.9 gpm 39.2 L/min 10.3 gpm |

| Pump type | Single gear |

| Maximum operating pressure | 172 bar 2495 psi |

| Draft control sensing | Position control |

| Remote control valves available | Up to two (optional) |

| 3-point hitch | |

| Type | Category 1 |

| Lift capacity, 24-in. behind link arms | 944 kg 2081.2 lb |

| Power take-off (PTO) | |

| Standard | At 2400 rpm: 540 rpm |

| Optional | |

| Control | Mechanical |

| Clutch | Transmission |

| Brake (for mid and rear PTO) | Wet disk |

| Engagement method | |

| Fluid capacities | |

| Crankcase with filter | 4.5 L 4.8 qt |

| Transmission and hydraulic system | 33 L 34.8 qt |

| Final drive | |

| Type | Spur gear |

| Differential lock | |

| Operator station | |

| Rollover protective structure | Type Foldable ASABE S478 |

| Platform - flat/straddle | Straddle |

| Gear shift location - console/floor | Right-hand side |

| Cab | |

| Compliance | |

| Visibility | |

| Air conditioning, temperature differential | |

| Doors | |

| Noise rating | |

| Seat equipment | |

| Dimensions | |

| Height | |

| Wheelbase | 1574 mm 62 in. |

| Front axle clearance | Minimum: 331 mm 13 in. Maximum: 353 mm 13.9 in. |

| Turning radius with brakes | 1.63 m 5.3 ft |

| Turning radius without brakes | |

| Limited slip differential | |

| Approximate shipping weight (open-station; cab) | OOS: 1288 kg 2840 lb Cab: Not applicable |

| Tires | |

| Front | R1 Bar: 7-14 R3 Turf: 27x8.5-15 R4 Industrial: 25x8.5-14 |

| Rear | R1 Bar: 11.2-24 R3 Turf: 41x14-20 R4 Industrial: 15-19.5 |

| Front tread range | |

| Rear tread spacing | |

| Miscellaneous | |

| Toolbox | Yes |

| Tilt steering wheel | No |

| 12-V Outlet | No |

Accessories and Attachments

Ballast

Ballast box shown with extension

Ballast box shown with extensionThe ballast box can be used to carry additional ballast for greater tractor stability.

A 9-in. high extension can be added to ballast box for even greater capacity.

A bushing kit is required for the ballast box to be used with the iMatch™ Quick Hitch.

BW14701 ballast box shown with BW15074 extension

BW14701 ballast box shown with BW15074 extension WP16011033 large ballast box

WP16011033 large ballast boxBallast boxes can be used to carry additional ballast for greater tractor stability.

NOTES:

1. Ballast box BW14701 has Category 1 pins and is compatible with a Category 1, 3-point hitch. It can be made Category 1 quick-hitch (iMatch™ hitch) compatible by adding BW15056 bushing kit.

2. The large ballast box (WP16011033) has Category 2 pins and is compatible with a Category 2, 3-point hitch. The large ballast box (WP16011033) is not quick-hitch-compatible.

3. Requires (2) R66432 bushing, (1) M115827 quick-lock pin, (1) R58262 pin, and (1) T12553 bushing to convert Category 1 ballast box to Category 2.

Draft Link

Drawbar

Engine

Engine coolant heater kit

Engine coolant heater kitAttached to the engine cylinder block, the engine coolant heater plugs into a 120-V electrical outlet to warm the engine for fast cold-weather starts.

NOTE: It is recommended to install optional engine coolant heater, transmission oil heater, and battery heating pad (A22400P - ordered through A and I) if operating machine in temperatures below -18 ⁰C (0⁰F).

Engine

Exhaust

Front Weights

Front Weights

Front Wheels And Tires

25 x 8.50 - 14 (6 PR, R4 Industrial, 2 Position) Front Wheels & Tires - BLV10851

27x8.50-15 (6PR, R3 Turf, 2 Position) Front Wheels & Tires - BLV10849

7-14 (6PR, R1 Bar, 2 Position) Front Wheels & Tires - BLV10860

Hydraulics

Lighting

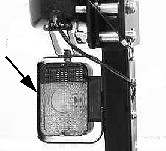

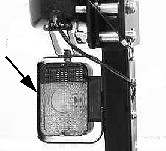

Rear work light

Rear work lightThis kit provides light to the rear of the tractor for evening work.

For open-station tractors only, this kit contains individual light.

Allow 30 minutes to install.

NOTE: Kit includes one rear light.

NOTE: Both the rear- and forward-work lights are compatible together and with the light-brush guard kits. The light kit contains a two-to-four pigtail that plugs into the main harness, as if only plugging one set of lights, providing two sets of plugs to use for forward and rear-work lights. The forward light is installed on top of the brush guard, and the rear light is installed inside the ROPS using the bolt holding the light and brush guard on.

NOTE: For 102E3 and 1026R Tractors – kit interference during backhoe operations (mounted inside ROPS) – use LVB25546 forward-light kit as an alternative.

The forward-lighting kit provides extra visibility when working in dark conditions. Lights attach to the brush guards located on the rollover protective structure (ROPS). Each kit contains two lights.

NOTE: Requires BLV10400 warning light brush guard kit and LVB26026 light kit harness. Not compatible with LVB25547 rear work light kit (1023E).

NOTE: Requires BLV10400 warning light brush guard kit. Not compatible with LVB25547 rear work light kit (1025R, 2025R, 2032R, 2038R, 3025E, 3032E, 3038E, 4105, 4044M, 4052M, 4066M).

NOTE: Requires BLV10620 premium warning light brush guard kit. Not compatible with LVB25547 rear work light kit (3033R, 3039R, 3046R, 4044R, 4052R, 4066R).

Rollover protective structure (ROPS) mounted LED work lights

An optional LED work light kit is available for all open-station compact utility tractors. These lights provide extra visibility when working in dark conditions and have 180-degree rotation to face forward or backward. The kit contains two lights and the mounting hardware required for installation.

This lighting kit is mounted to the warning light brush guard kit, which is mounted to the ROPS and requires attachment BLV10400 for installation.

The halogen work light kit attachment is still available (LVB25546).

Shown on 4000 TEN Series Tractor

Shown on 4000 TEN Series TractorROPS warning-light brush guards protect turn signal/warning lights from damage caused by low branches on trees.

For open-station tractors only.

Two guards included in each kit.

Shown on 4000 TEN Series Tractor

Shown on 4000 TEN Series TractorROPS warning-light brush guards protect turn signal/warning lights from damage caused by low branches on trees.

For open-station tractors only.

Two guards included in each kit.

Miscellaneous

Safety chain support

Safety chain support- Provides necessary tractor parts to accept implement safety chains

- Attaches to tractor drawbar ahead of hitch pin

- Order safety chain from implement section

Miscellaneous

Open Operator's Station

Standard canopy mounted to 5M Series ROPS

Standard canopy mounted to 5M Series ROPSThe standard canopy attaches to the tractor's rollover protective structure (ROPS) to protect operators from inclement weather.

Additional mounting brackets and hardware bundles are required to install the canopy to the ROPS.

Standard canopy kit

Standard canopy kit Deluxe canopy kit

Deluxe canopy kitMounting brackets and hardware bundles are required to adapt a canopy to the tractor rollover protective structure (ROPS).

Large seat cover

Large seat cover- Cushioned seat for extra comfort

- Fabric coated for maximum water resistance and repellency

- Elastic cord locks around safety sign on seat back

- Elastic cord in bottom hem for a custom fit

- Handy zippered storage case

Ordering information

Please contact your local John Deere dealer for availability and pricing information.

Large seat cover

Order number: LP95233

Power Take-off (Pto)

Rear Axle

Rear Wheel Weights

Rear wheel weight

Rear wheel weight- Provide additional traction and stability

- Starter and additional weight for 15-in. wheel, 16.5-in. wheel, 17.5-in. wheel, and 19.5-in. wheel

- Up to three weights per wheel can be added

Attaching Hardware for Starter Rear Wheel Weight, 60 lb for 16 in. and 19.5 in. Wheel - BM19938

Rear wheel weight

Rear wheel weight- Provide additional traction and stability

- Starter and additional weight for 15-in. wheel, 16.5-in. wheel, 17.5-in. wheel, and 19.5-in. wheel

- Up to three weights per wheel can be added

Rear Wheels And Tires

Provide added traction in snowy and icy conditions.

Provide added traction in snowy and icy conditions.

Rear Wheels and Tires

11.20-24 (6PR, R1 Bar, 1 Position) Rear Wheels & Tires - BLV10937

15-19.5 (6PR, R4 Industrial, 1 Position) Rear Wheels and Tires - BLV10936

41x14-20 (4PR, R3 Turf, 1 Position) Rear Wheels & Tires - BLV10942

Three-point Hitch

3-Point Hitch Tractor Receiver Hitch - LP25001

One of the greatest operator concerns involves difficulty in attaching tractor implements. John Deere has addressed this issue with the iMatch Quick-Hitch:

- All implements require a set of bushings in order for the attachment to fit and work properly with the iMatch Quick-Hitch. One set of bushings comes with the iMatch Quick-Hitch.

NOTE: All implements (box blades, tillers, rear blades, landscape rakes, etc.) require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier.

iMatch Quick-Hitch

iMatch Quick-Hitch iMatch Quick-Hitch with 3-Point Hitch Disk Harrow

iMatch Quick-Hitch with 3-Point Hitch Disk HarrowOne of the greatest operator concerns involves difficulty in attaching tractor implements. John Deere has addressed this issue with the iMatch Quick-Hitch.

The iMatch Quick-Hitch provides easy hookup and a guaranteed fit for all Category 1 implements designed to meet the ASAE Category 1 Standard S278.6 for quick-attach hitches.

- All implements require a set of bushings in order for the attachment to fit and work properly with the iMatch Quick-Hitch. One set of bushings comes with the iMatch Quick-Hitch.

NOTE: All implements (box blades, tillers, rear blades, landscape rakes, etc.) require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier (see dimensions below).

- Upper bushing

- Inside diameter of 0.76 in. to 0.77 in. (19 mm to 20 mm)

- Outside diameter of 1.24 in. to 1.25 in. (31 mm to 32 mm)

- Lower bushings

- Inside diameter of 0.88 in. to 0.89 in. (22 mm to 23 mm)

- Outside diameter of 1.43 in. to 1.44 in. (36 mm to 37 mm)

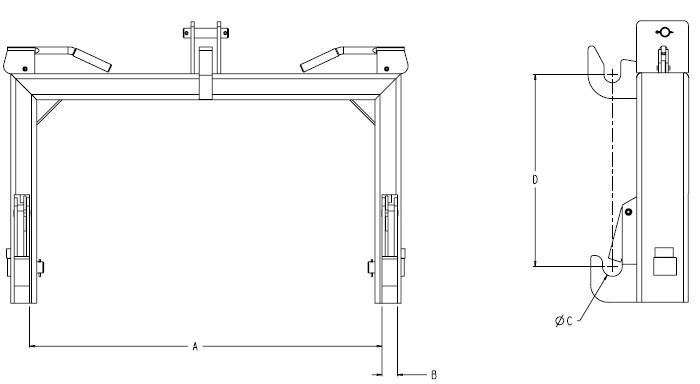

iMatch Quick-Hitch dimensions

iMatch dimensions

iMatch dimensions

| Dimensions designated | Millimeters (minimum) | Millimeters (maximum) |

| 'A' lower socket inside span | 686.56 | 689.61 |

| 'B' lower socket width | 27.94 | 29.46 |

| 'C' lower socket diameter | 38.1 | 38.61 |

| 'D' upper hook vertical spacing | 375.41 | 377.96 |

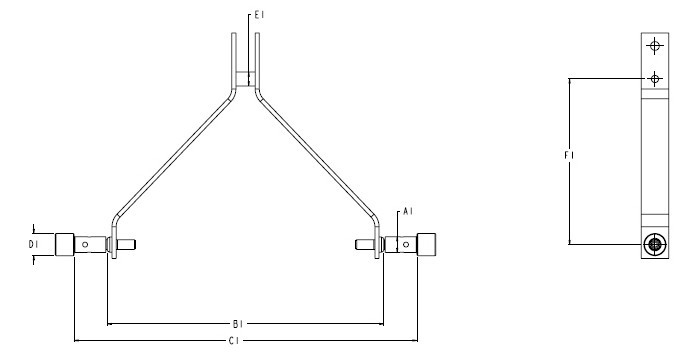

iMatch Quick-Hitch implement geometry

iMatch implement dimensions

iMatch implement dimensions

| Dimensions designated | Millimeters (minimum) | Millimeters (maximum) |

| 'A' lower hitch pin or adapter outside diameter | 36.33 | 36.58 |

| 'B' lower hitch pin inner shoulder spread | 681.0 | 684.3 |

| 'C' lower hitch pin outer shoulder spread | 750.83 | 753.88 |

| 'D' lower hitch pin inner/outer shoulder diameter | 50.55 | 63.75 |

| 'E' coupler mast pin diameter | 31.50 | 31.75 |

| 'F' coupler mast pin vertical spacing | 379.48 | 382.53 |

Weights

Reviews

7 reviews

- Filter

- Star Rating

- Value

- Quality